Umbhobho wokufudumeza wombane womphunga

Umgaqo wokusebenza

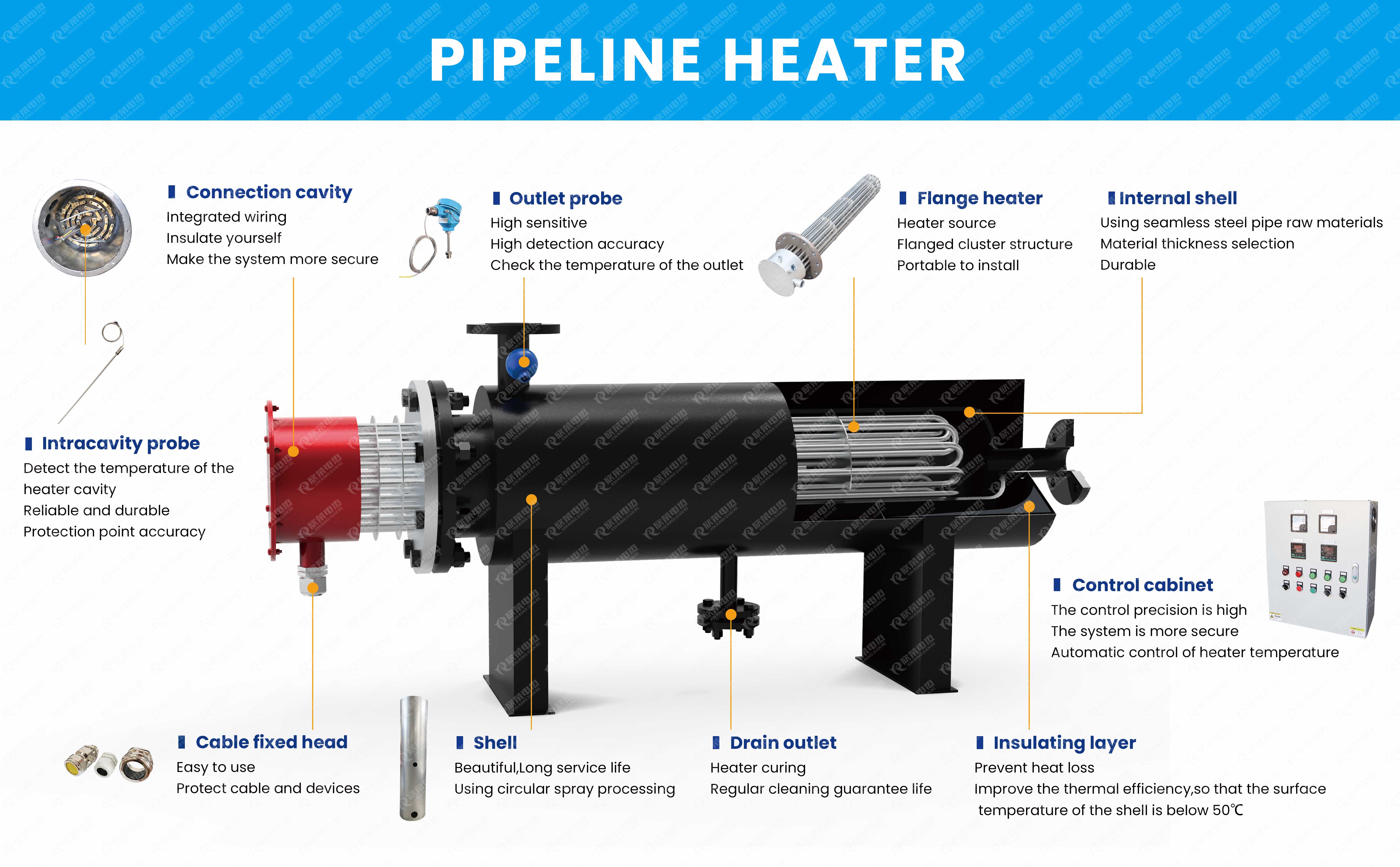

Isifudumezi sombane sivelisa ubushushu: Isixhobo sokufudumeza sombane kwisifudumezi yinxalenye engundoqo yokuvelisa ubushushu. Xa umsinga wombane udlula kwezi zinto, zivelisa ubushushu obuninzi.

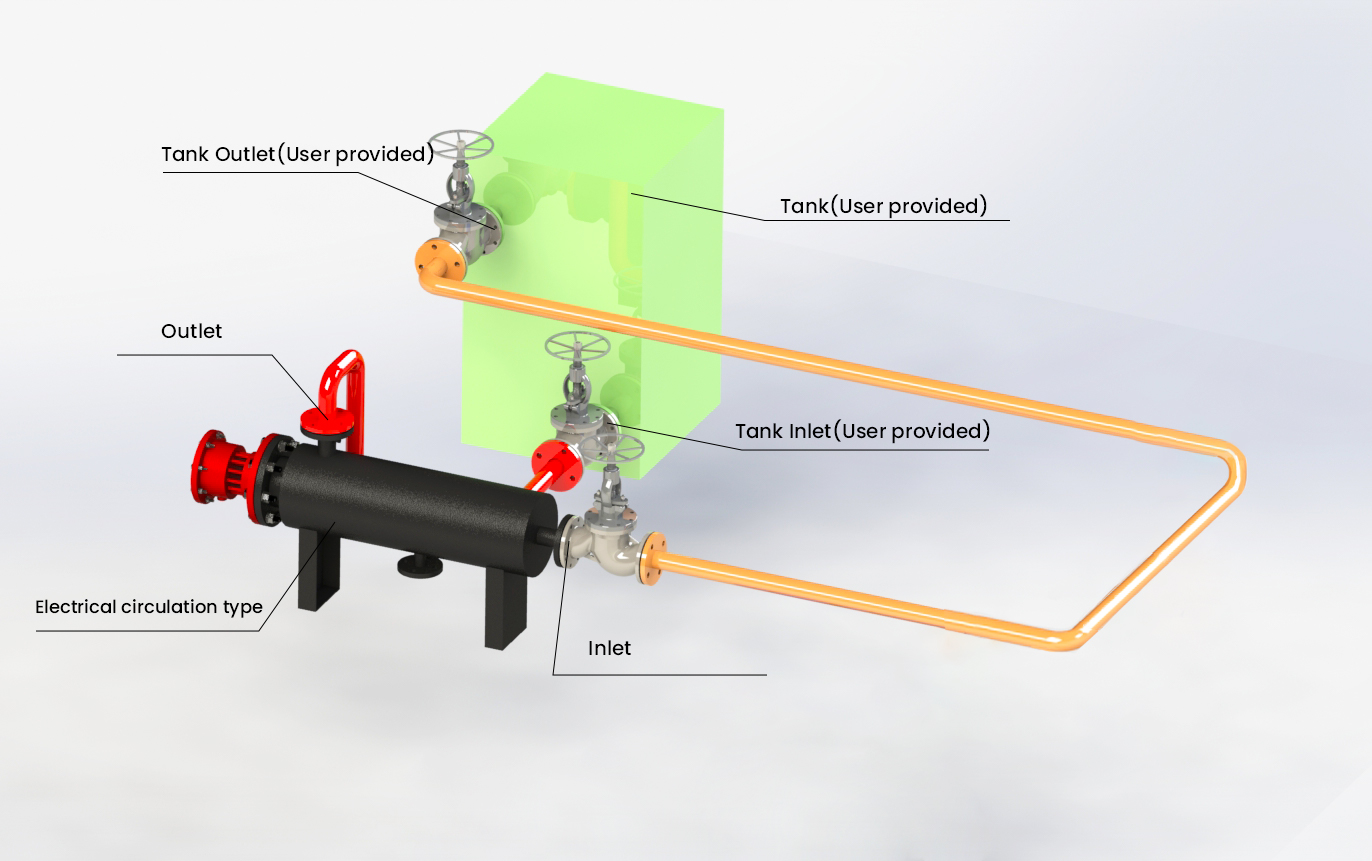

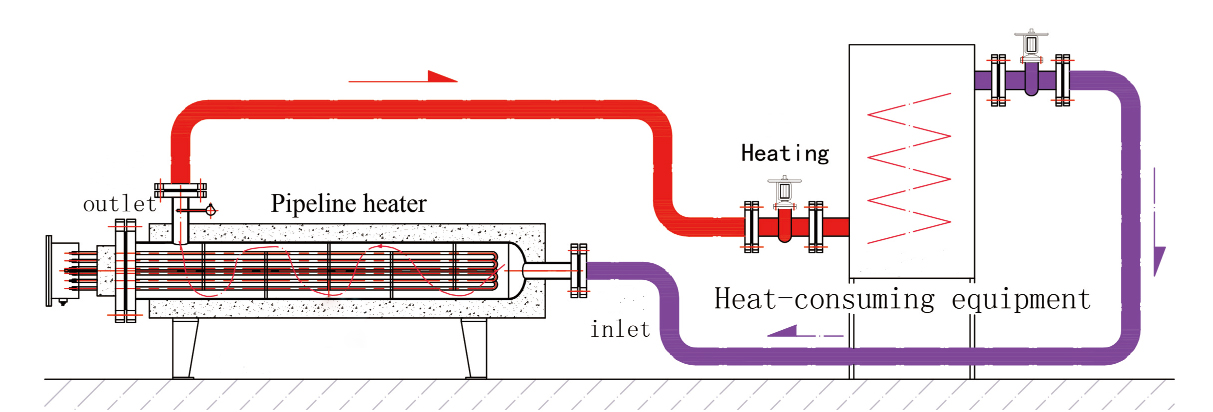

Ukufudumeza okunyanzeliswayo: Xa i-nitrogen okanye enye into ephakathi idlula kwisifudumezi, impompo isetyenziselwa ukunyanzela i-convection, ukuze i-medium ihambe kwaye idlule kwindawo yokufudumeza. Ngale ndlela, i-medium, njenge-heat carrier, inokuthatha ngokufanelekileyo ukushisa kwaye idlulisele kwinkqubo efuna ukufudumeza.

Ulawulo lobushushu: I-heater ixhotyiswe ngenkqubo yokulawula kubandakanya inzwa yokushisa kunye nomlawuli we-PID. Ezi zixhobo zisebenza kunye ukuze zilungelelanise ngokuzenzekelayo amandla okuphuma kwe-heater ngokweqondo lokushisa lokuphuma, ukuqinisekisa ukuba ukushisa okuphakathi kuzinzile kwixabiso elimiselweyo.

Ukukhuselwa kokushisa: Ukuze kuthintelwe umonakalo ogqithiseleyo kwinto yokufudumala, i-heater nayo ixhotyiswe ngezixhobo zokukhusela ukushisa. Ngokukhawuleza ukuba kufunyenwe ukushisa, isixhobo sinqumla ngokukhawuleza ukunikezelwa kwamandla, ukukhusela into yokufudumala kunye nenkqubo.

Iinkcukacha zemveliso zibonisa

Inzuzo yemveliso

I-1, i-medium inokufudumala kwiqondo lokushisa eliphezulu kakhulu, ukuya kuthi ga kwi-850 ° C, ukushisa kwegobolondo malunga ne-50 ° C kuphela;

2, ukusebenza kakuhle: ukuya kuthi ga kwi-0.9 okanye ngaphezulu;

I-3, izinga lokufudumeza kunye nokupholisa ngokukhawuleza, ukuya kuthi ga kwi-10 ℃ / S, inkqubo yokulungelelanisa ikhawuleza kwaye izinzile. Akuyi kubakho i-lead lead kunye ne-lag phenomenon ye-medium elawulwayo, eya kubangela ukuqhutyelwa kweqondo lokushisa lokulawula, elilungele ulawulo oluzenzekelayo;

I-4, iipropati ezilungileyo zoomatshini: ngenxa yokuba umzimba wayo wokufudumeza uyinto ekhethekileyo ye-alloy, ngoko ke phantsi kwempembelelo yoxinzelelo oluphezulu lokuhamba komoya, kungcono kunayo nayiphi na impawu yokufudumeza umzimba kunye namandla, efuna ixesha elide eliqhubekayo lokufudumeza umoya kunye novavanyo lwezincedisi kunenzuzo ngakumbi;

5. Xa ingaphuli inkqubo yokusetyenziswa, ubomi bunokuba bubude amashumi eminyaka, ehlala ixesha elide;

6, umoya ococekileyo, ubungakanani obuncinci;

I-7, i-heater yepayipi ingenziwa ngokweemfuno zabasebenzisi, iintlobo ezininzi zokufudumala zombane zomoya.

Ushwankathelo lwesicelo semeko yokusebenza

Ukufudumeza okwesibini Izifudumezi zombane zisetyenziselwa ukufudumeza umphunga ukunyusa ubushushu bawo emva kokuba sele wenziwe.

Oku kudla ngokufezekiswa ngokongeza isifudumezi sombane ekupheleni kombhobho womphunga ukuze kuqinisekiswe ukuba ubushushu beradiyetha ekupheleni kombhobho bufikelela kwixabiso elimiselweyo, ngaloo ndlela kwandisa isiphumo sokufudumeza kwendawo okanye ukufezekisa ubushushu bomphunga obufunekayo kwisixhobo se-thermal terminal, kwaye inkqubo yokufudumeza ayitshintshi uxinzelelo lomphunga kwindawo yokuphuma.

Ngenxa yokungazinzi kokuhamba kwe-steam medium, ulawulo luhlala lulawulwa ngokuchaneka kwe-thyristor ukuqinisekisa ukuzinza kweqondo lokushisa lomphunga.

Isishwankathelo, umgaqo wokusebenza we-steam yesibini yokufudumeza i-heater yombane ibandakanya inkqubo yokuguqula amandla ombane kumandla obushushu, ukulawula ngokuchanekileyo ukuveliswa komphunga kunye nokufudumeza okwesibini ngenkqubo yokulawula ngokuzenzekelayo, kunye noyilo lwenkqubo yokukhusela ukhuseleko, ukuqinisekisa ukusebenza kwayo ngokufanelekileyo nangokukhuselekileyo.

Isicelo semveliso

Isifudumezi sombhobho sisetyenziswa kakhulu kwi-aerospace, ishishini lezixhobo, ishishini lemichiza kunye neekholeji kunye neeyunivesithi kunye nolunye uphando lwesayensi kunye nelebhu yemveliso. Ilungele ngokukodwa ukulawulwa kweqondo lokushisa oluzenzekelayo kunye nokuhamba okukhulu kwenkqubo yokushisa ephezulu edibeneyo kunye novavanyo lwe-accessory, i-medium yokufudumeza yemveliso ayinayo i-conductive, i-non-burning, i-non-explosion, i-chemical corrosion, akukho ukungcola, ikhuselekile kwaye inokwethenjelwa, kwaye indawo yokufudumeza ikhawuleza (iyalawuleka).

Ityala lokusetyenziswa kwabathengi

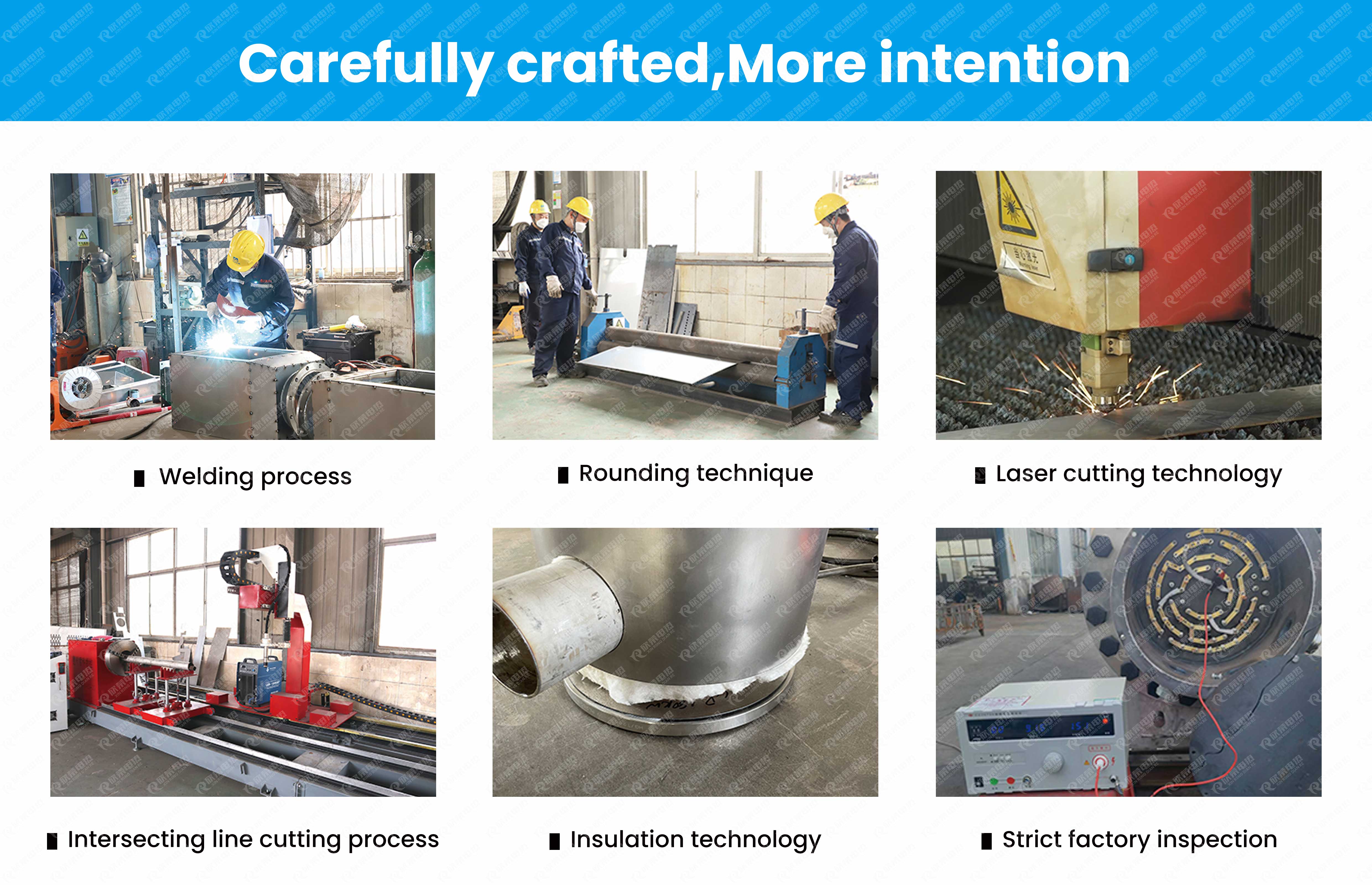

Ukusebenza kakuhle, ukuqinisekiswa komgangatho

Sinyanisekile, sinobuchule kwaye siyazingisa, ukukuzisela iimveliso ezigqwesileyo kunye nenkonzo esemgangathweni.

Nceda uzive ukhululekile ukusikhetha, masingqine amandla omgangatho kunye.

Isatifikethi kunye nesiqinisekiso

Ukupakishwa kwemveliso kunye nokuthutha

Ukupakishwa kwezixhobo

1) Ukupakisha kwiimeko zokhuni ezithunyelwa ngaphandle

2) I-tray inokwenziwa ngokwezifiso ngokweemfuno zabathengi

Ukuthuthwa kwempahla

1) Express (umyalelo wesampuli) okanye ulwandle (umyalelo wesambuku)

2) Iinkonzo zokuthumela kwihlabathi jikelele